Imagine a world where the very air you breathe could be precisely tailored to your needs, delivering a vital boost of oxygen without the hassle of heavy tanks or constant refills. That's not science fiction; it's the everyday reality enabled by the oxygen concentrator, a deceptively simple device that performs a small miracle by essentially "scrubbing" nitrogen right out of the air around you.

If you or a loved one relies on supplemental oxygen, understanding how oxygen concentrators work isn't just technical knowledge—it's empowering. It demystifies the machine, clarifies its purpose, and underscores its importance in managing various health conditions, from chronic respiratory issues to temporary post-illness recovery. Let's pull back the curtain on this essential technology, exploring its inner workings, its diverse applications, and what you need to know to use it safely and effectively.

At a Glance: Oxygen Concentrators

- What it is: A device that separates nitrogen from ambient air to deliver a concentrated, oxygen-enriched gas stream (typically 90-95% pure oxygen).

- How it works: Primarily through a process called Pressure Swing Adsorption (PSA), using special materials called molecular sieves to "catch" nitrogen.

- Main Uses: Oxygen therapy for medical conditions (COPD, asthma, heart failure), industrial processes, and supplemental oxygen for altitude sickness or athletic recovery.

- Types: Stationary (for home use, plug-in) and Portable (battery-powered, lighter for travel).

- Key Benefits: Continuous, unlimited oxygen supply, safer than traditional tanks, and improves quality of life.

- Critical Safety: Requires a power source, and oxygen significantly increases fire risk. Always keep away from open flames and sparking devices.

- Important: Prescribed by a healthcare provider, who determines flow settings and usage duration.

Your Personal Air Filter: What an Oxygen Concentrator Really Does

At its heart, an oxygen concentrator is a highly specialized air filter—but not one for dust or allergens. Instead, it's designed to filter out the most abundant gas in our atmosphere: nitrogen. Our air is roughly 21% oxygen, 78% nitrogen, and 1% other trace gases. For individuals whose lungs struggle to efficiently extract enough oxygen from this mix, a concentrator steps in to deliver a much richer supply.

Think of it as a selective sieve. While a traditional oxygen tank provides pure, pre-bottled oxygen, a concentrator generates oxygen on demand by taking in ordinary room air, isolating the oxygen molecules, and delivering them to you. This ingenious approach offers a continuous, virtually limitless supply, eliminating the need for refills or the constant worry of running out.

More Than Medical: The Many Uses of Oxygen Concentrators

While most people associate oxygen concentrators with healthcare, these versatile machines have a broader reach, making a significant impact in various sectors.

Breathing Easier: Medical Applications

The primary and most recognized role of oxygen concentrators is in medical oxygen therapy. They are prescribed by healthcare providers for individuals struggling with conditions that impair their ability to absorb enough oxygen from ambient air. This can include:

- Chronic Obstructive Pulmonary Disease (COPD): A group of progressive lung diseases, including emphysema and chronic bronchitis.

- Asthma: A condition where airways narrow and swell, making breathing difficult.

- Cystic Fibrosis: A genetic disorder that primarily affects the lungs and digestive system.

- Heart Failure: When the heart can't pump enough blood to meet the body's needs.

- Lung Cancer: Malignant tumors that form in lung tissues.

- Pneumonia: An infection that inflames the air sacs in one or both lungs.

- Respiratory Trauma: Injuries to the respiratory system.

- Severe Sleep Apnea: When breathing repeatedly stops and starts during sleep.

For these patients, an oxygen concentrator provides a safer, often more convenient, and significantly less expensive alternative to traditional oxygen cylinders or bulky liquid oxygen systems, especially for home use, in portable clinics, or in remote areas where supply chains for tanks might be challenging.

Powering Progress: Industrial Applications

Beyond individual health, oxygen concentrators—often referred to as oxygen gas generators or oxygen generation plants in this context—are critical for various industrial processes. Here, they provide an economical source of oxygen for:

- Chemical Oxidation: Crucial in many chemical manufacturing processes.

- Paper Pulp Bleaching and Delignification: Enhancing the brightness and quality of paper.

- Glass Furnace Firing: Achieving the high temperatures needed for glass production.

- Waste Burning: Improving the efficiency and completeness of incineration processes.

The ability to generate oxygen on-site reduces logistical complexities and costs associated with transporting and storing large volumes of oxygen. If you're curious about these larger-scale systems, you can explore our o2 generator guide for a deeper dive.

Beyond the Clinic: Other Uses

You might also encounter oxygen concentrators in less conventional settings:

- High Altitudes: Providing supplemental oxygen to prevent altitude sickness for climbers or those living in high-elevation regions.

- Athletic Performance: Some athletes use supplemental oxygen to aid recovery, reduce lactic acid buildup, potentially increase energy, and improve training capacity. While research is ongoing, the principle is to optimize oxygen delivery to tired muscles.

From improving health outcomes to fueling industrial giants, the technology at the heart of an oxygen concentrator is truly transformative.

The Magic Behind the Machine: How Concentrators Work

At the core of every oxygen concentrator is a sophisticated yet elegantly simple mechanism designed to perform that crucial separation of nitrogen from oxygen. While membrane technology offers an alternative approach, the vast majority of concentrators—especially those used medically—rely on a process called Pressure Swing Adsorption (PSA).

1. Pressure Swing Adsorption (PSA): The Workhorse

Imagine a sponge that only absorbs nitrogen. That's essentially what the heart of a PSA oxygen concentrator does. The "sponge" in this case is a special material called a molecular sieve, typically made from zeolite minerals. Zeolites have a porous structure with specific pore sizes that preferentially adsorb (trap) smaller nitrogen molecules under pressure, while allowing larger oxygen molecules to pass through.

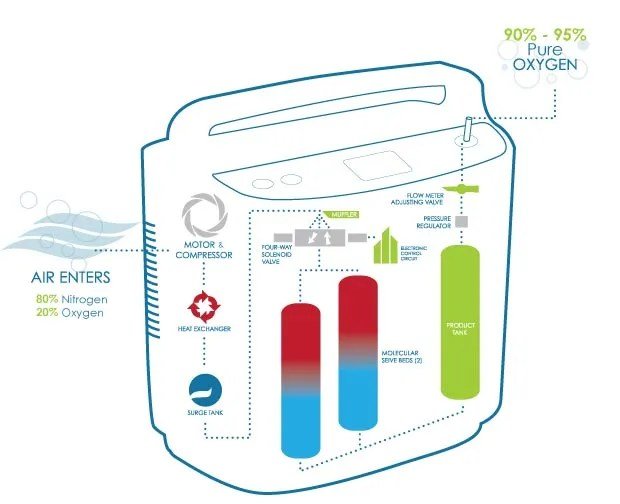

Here's a step-by-step breakdown of the PSA process:

- Air Intake: It all begins with a built-in air compressor. This powerful fan draws in ambient air from the room, just like you might take a deep breath. This air is then filtered to remove dust, pollen, and other particulate matter, ensuring a clean supply.

- Compression: The compressor then pressurizes this filtered air. This increased pressure is crucial for the next step.

- Adsorption in the Sieve Bed (Cylinder 1): The compressed air is directed into one of two identical cylinders, each packed with those tiny zeolite pellets. As the air rushes over the zeolite at this elevated pressure (often around 2.5 times atmospheric pressure, or 20 psi/138 kPa gauge), the nitrogen molecules are "adsorbed"—they stick to the surface of the zeolite, trapped within its microscopic pores.

- Oxygen Collection: Since the nitrogen is trapped, the remaining gas—now highly concentrated oxygen (typically 90-95% pure)—flows out of this cylinder. This oxygen-rich gas then moves to a small pressure-equalizing reservoir (a buffer tank) to ensure a steady, consistent flow before being delivered to the user through a cannula or mask.

- Regeneration (Cylinder 2): While Cylinder 1 is busy adsorbing nitrogen and delivering oxygen, the other cylinder (Cylinder 2) is simultaneously undergoing a regeneration process. Here, the pressure is drastically reduced. This "swing" in pressure is key: as the pressure drops, the nitrogen molecules that were previously trapped within the zeolite are released, or "desorbed." This expelled nitrogen, along with any trace gases, is then vented back into the ambient air, completely harmlessly.

- The Cycle Continues: After a set period (often around 20 seconds in older units, faster in modern ones), the roles of the two cylinders reverse. Cylinder 2 begins to pressurize and adsorb nitrogen, delivering oxygen, while Cylinder 1 depressurizes and regenerates. This continuous, alternating cycle allows for a constant supply of concentrated oxygen.

Performance Over Time: Early home units (before 1999) could typically supply up to 5 liters per minute (L/min) of 90+% oxygen. Modern concentrators have improved significantly, with many medical units now providing up to 10 L/min, and advanced multi-bed industrial designs capable of producing over 960 L/min with ramp-up times often less than 2 minutes. This constant innovation means more efficient, powerful, and reliable oxygen generation.

2. Membrane Gas Separation: A Different Approach

While less common for individual medical use due to current efficiency limitations for high-purity oxygen, membrane gas separation is another method employed, particularly in industrial settings. This technology utilizes a permeable membrane (often made from polymers or ceramics) to separate gas mixtures.

Here's the basic idea:

- Pressure Difference: Air is pushed across a specialized membrane.

- Differential Permeation: Different gases permeate (pass through) the membrane at varying rates based on their molecular size, diffusivity, and solubility within the membrane material. Think of it like a very fine filter where some molecules squeeze through faster than others.

- Separation: Oxygen molecules might permeate faster or be collected on one side (e.g., upstream), while nitrogen collects on the other (e.g., downstream), leading to a separation of the gas stream.

As of 2016, membrane technology was capable of producing 10 to 25 tonnes of 25 to 40% oxygen per day. While the purity isn't typically as high as PSA for medical applications, it offers advantages in certain industrial processes where bulk oxygen at lower purity is sufficient.

Understanding these mechanisms illuminates the remarkable engineering that goes into every breath delivered by an oxygen concentrator.

Finding Your Fit: Types of Oxygen Concentrators

Oxygen concentrators come in different forms to suit various lifestyles and needs. The primary distinction lies in their size, power source, and portability.

1. Stationary Oxygen Concentrators

These are the workhorses of home oxygen therapy.

- Size and Weight: Typically weigh around 10 kilograms (22 lbs). While not designed for constant carrying, most models include handles or wheels, making them relatively easy to move from room to room.

- Power Source: They run on standard household electricity, plugging into a wall outlet.

- Oxygen Output: Generally offer a higher and more consistent oxygen output compared to portable units, often delivering up to 10 liters per minute (LPM) of continuous flow.

- Features: Many stationary units come with battery backups or can be hooked up to a small compressed oxygen tank, providing a crucial safety net in case of a power outage. This backup is essential for maintaining therapy during unexpected interruptions.

- Best For: Individuals who require consistent, higher-flow oxygen therapy primarily at home.

2. Portable Oxygen Concentrators (POCs)

Designed for freedom and mobility, POCs empower users to maintain an active lifestyle.

- Size and Weight: Significantly smaller and lighter than stationary units, with some weighing as little as a few pounds. They often come with carry bags, shoulder straps, or even backpack options.

- Power Source: Powered by rechargeable lithium-ion batteries, allowing for several hours of use away from a power outlet. They also typically include AC adapters for home charging and DC adapters for use in a car.

- Oxygen Output: Oxygen output is generally lower than stationary units.

- Pulse-Flow (Demand Flow): Most POCs operate in a "pulse-flow" or "demand flow" mode. This means they deliver a burst of oxygen only when the patient inhales, conserving battery life and oxygen. This mode is excellent for daytime activity.

- Continuous Flow: Some larger portable units, particularly those designed for overnight use or higher prescriptions, also offer a continuous-flow option. This is often necessary when paired with devices like CPAP machines, which require a steady stream of oxygen throughout the breathing cycle.

- Travel Approved: Portable oxygen concentrators are approved by the Federal Aviation Administration (FAA) for use on commercial airlines. However, it's always wise to confirm your specific model with your airline in advance, as policies can vary slightly.

- Best For: Individuals who need supplemental oxygen but want the flexibility to travel, run errands, or simply move around their home and community without being tethered to a wall outlet or heavy tank.

Choosing between stationary and portable units, or often using a combination of both, depends on your specific medical needs, activity level, and lifestyle. Your healthcare provider will help you determine the most appropriate type and settings.

A Look Back: The History of Oxygen Concentrators

The journey of the oxygen concentrator from concept to widespread medical device is relatively recent, rooted in mid-20th-century scientific breakthroughs.

The fundamental technology that makes concentrators possible—the molecular sieve—was actually invented by Union Carbide Corporation in the 1950s. These synthetic zeolites provided the selective adsorption capabilities needed to separate gases like nitrogen and oxygen.

It wasn't until the early 1970s that home medical oxygen concentrators themselves were invented. Companies like Union Carbide (leveraging their molecular sieve expertise) and Bendix Corporation were among the early manufacturers to bring these innovative devices to market.

However, the widespread adoption of concentrators in homes received a significant boost in the United States in the mid-1980s. A pivotal change in US Medicare payment policies shifted from a fee-for-service model (where providers were paid for each oxygen tank delivered) to a flat monthly rate for home oxygen therapy. This new structure made concentrators—which offered a continuous supply without recurring delivery costs—a far more economical choice for cost control, rapidly increasing their use over traditional oxygen cylinders. This policy shift fundamentally changed how home oxygen therapy was delivered, cementing the concentrator's place as a cornerstone device.

The Upside: Why Concentrators Are a Game Changer

Oxygen concentrators have revolutionized how people receive supplemental oxygen, offering numerous advantages over older methods.

- Continuous, Unlimited Supply: This is arguably the biggest benefit. As long as you have a power source (electricity or charged batteries), a concentrator can generate oxygen indefinitely. This eliminates the anxiety of running out of oxygen, the need for frequent tank refills or deliveries, and the logistical challenges of managing multiple heavy cylinders.

- Enhanced Safety: Unlike oxygen cylinders, which store highly pressurized oxygen and can increase combustion rates if ruptured or leaking, concentrators do not store oxygen under high pressure. They produce it on demand. This makes them significantly safer, particularly in environments like homes, or even in military or disaster situations where the risks of fire or explosion are heightened.

- Improved Quality of Life: For individuals with chronic respiratory conditions, consistent and reliable oxygen therapy can dramatically improve quality of life. Users often experience:

- Better Breathing: Reducing shortness of breath and making daily activities more manageable.

- Increased Energy Levels: Adequate oxygen supply to organs and muscles can combat fatigue.

- Promoted Better Sleep: Alleviating nocturnal desaturation and improving sleep architecture, leading to more restful nights.

- Cost-Effectiveness: Over the long term, concentrators are generally more cost-effective than repeatedly purchasing or refilling oxygen tanks, particularly for continuous, high-volume users.

Staying Safe: Disadvantages & Critical Precautions

While oxygen concentrators offer life-changing benefits, they also come with specific considerations and require careful adherence to safety guidelines. Understanding these is paramount for safe and effective use.

1. Power Dependency

- The Challenge: Oxygen concentrators, whether stationary or portable, rely on a power source to operate. Stationary units need household electricity, while portable units need charged batteries. A power outage or a dead battery means no oxygen.

- Actionable Insight: Always have a backup plan. This might include:

- Battery Backups: For stationary units, consider models with battery backup systems.

- Spare Batteries: For portable units, carry fully charged spare batteries, especially when traveling.

- Alternative Oxygen Source: Discuss with your healthcare provider the possibility of having a small, compressed oxygen tank (sufficient for several days) available as an emergency backup in case of extended power outages.

- Emergency Plan: Know what to do and who to call if you lose power for an extended period.

2. Fire Hazard: Oxygen Fuels Flames

- The Danger: Oxygen itself is not flammable, but it dramatically increases the rate and intensity of combustion. This means a small spark or flame can quickly become a raging fire or even cause an explosion in an oxygen-enriched environment.

- Actionable Insight: Keep Your Distance:

- Always maintain a safe distance of at least 10 feet (3 meters) between your oxygen concentrator (and any oxygen supply) and all heat sources and flammable materials.

- NO Smoking: This is non-negotiable. Absolutely no smoking, vaping, or open flames (candles, fireplaces, gas stoves, grills) when oxygen is in use. Inform visitors of this critical rule.

- Flammable Products: Avoid using products containing oil, grease, petroleum jelly (like Vaseline), alcohol, or aerosol sprays near your oxygen equipment. These can ignite fiercely in an oxygen-rich environment. Read product labels carefully.

- Sparking Electrical Equipment: Do not use devices that can generate sparks near your concentrator or oxygen cannula. This includes hair dryers, electric blankets, space heaters, electric razors, and even poorly maintained electrical outlets.

- Important: This precaution applies to anyone in the vicinity of the oxygen concentrator or the tubing delivering oxygen to the user.

3. Health Risks: Too Much or Too Little Oxygen

- The Danger: Using an oxygen concentrator incorrectly—either at the wrong flow rate or for the wrong duration—can lead to serious health complications.

- Oxygen Poisoning (Hyperoxia): Too much oxygen can be harmful, leading to symptoms like dizziness, confusion, headaches, nausea, and vomiting. In severe cases, it can damage the lungs and central nervous system.

- Hypoxia: Too little oxygen (if the concentrator isn't working properly or the settings are too low) can also be dangerous, indicated by symptoms such as restlessness, confusion, headaches, a slow heart rate, and cyanosis (a bluish tint to the skin, lips, or nail beds).

- Actionable Insight: Monitor and Consult:

- Pulse Oximeter: Your healthcare provider will likely recommend a pulse oximeter, a small device that clips onto your finger to monitor your blood oxygen levels (SpO2). Regularly checking your SpO2 helps ensure you're receiving the correct amount of oxygen.

- Follow Prescriptions: Never adjust your oxygen flow rate or usage duration without consulting your healthcare provider. Your prescription is tailored to your specific needs.

- Device Malfunction: Many modern units have built-in alarms that sound if oxygen purity drops below 80% or if there's a fault. If your concentrator alarms, or if you experience symptoms of oxygen poisoning or hypoxia, contact your healthcare provider immediately. Routine device checks and maintenance are also advisable.

Your safety is paramount. Treat your oxygen concentrator with respect, follow all prescribed guidelines, and be vigilant about potential hazards.

Beyond Medical: Industrial Oxygen Concentrators

While the principles of separating nitrogen from oxygen remain the same, industrial oxygen concentrators, often called "oxygen generators," operate on a much grander scale and for different purposes than their medical counterparts.

- Higher Pressures and Flows: Industrial units are engineered to produce massive volumes of oxygen at significantly higher pressures and flow rates, capable of supplying entire manufacturing plants or large-scale processes.

- Vacuum Swing Adsorption (VSA): In addition to PSA, industrial applications often utilize Vacuum Swing Adsorption (VSA). VSA uses a vacuum to desorb nitrogen from the molecular sieve, which can be more energy-efficient for very large systems compared to simple depressurization.

- "Oxygen Generators": This term is frequently used to distinguish them from medical devices, emphasizing their role in generating oxygen for industrial uses rather than direct patient care.

- Regulatory Differences: It's crucial to understand that industrial oxygen generators are not FDA-approved for direct medical use. If oxygen from an industrial generator is to be integrated into a medical oxygen supply system (e.g., for a hospital), it requires extensive additional filtration, purification, and rigorous regulatory approval to ensure it meets the strict purity and safety standards for human consumption.

These robust systems are vital for diverse industries, showcasing the incredible versatility of oxygen generation technology.

The Pandemic's Echo: Oxygen Concentrators and COVID-19

The COVID-19 pandemic brought oxygen concentrators into the global spotlight as never before. The severe respiratory nature of the virus meant that a significant number of patients required supplemental oxygen to survive. This led to an unprecedented surge in demand for oxygen concentrators worldwide, particularly in regions where healthcare infrastructure was strained.

During peak waves, especially in countries like India, the demand far outstripped supply. This crisis spurred:

- Rapid Manufacturing Expansion: Existing manufacturers ramped up production to meet the urgent global need.

- Local Production Initiatives: Many countries initiated or scaled up local manufacturing of oxygen concentrators, often with international support.

- Open-Source Designs: Engineers and innovators developed open-source designs for concentrators, aiming to make the technology more accessible and enable faster local fabrication in resource-limited settings.

The pandemic underscored the critical importance of oxygen therapy and highlighted the vital role of oxygen concentrators as a frontline medical device, capable of delivering life-saving support outside of traditional hospital settings.

Making the Most of Your Concentrator: Practical Tips

Using an oxygen concentrator effectively and safely goes beyond simply turning it on. Here are some practical tips to ensure you get the most out of your device:

- Follow Your Prescription Exactly: Your healthcare provider has determined the specific oxygen flow rate (in liters per minute, L/min) and the duration of use required for your condition. This prescription is personalized; deviating from it can be harmful. Never adjust your settings without professional medical advice. Most users require supplemental oxygen for at least 15 hours daily, with some needing it 24 hours a day.

- Monitor Your Oxygen Levels: A pulse oximeter is an invaluable tool for anyone on oxygen therapy. Regularly check your blood oxygen saturation (SpO2) to confirm that the concentrator is delivering adequate oxygen and that your body is responding appropriately. Discuss target SpO2 ranges with your doctor.

- Maintain Your Device:

- Clean Filters Regularly: Your concentrator has air filters that need to be cleaned (usually washed with soap and water) or replaced regularly according to the manufacturer's instructions. Clogged filters reduce efficiency and can damage the machine.

- Check Tubing and Cannula: Inspect your oxygen tubing and nasal cannula for kinks, cracks, or blockages. Replace them as recommended by the manufacturer or your doctor, typically every 2-4 weeks for cannulas and every few months for tubing.

- Professional Servicing: Schedule periodic professional servicing as recommended by the manufacturer to ensure optimal performance and longevity.

- Ensure Good Ventilation: While the concentrator vents nitrogen harmlessly, operating it in a well-ventilated space is always a good practice. Avoid placing it in small, enclosed spaces or against walls that could impede airflow.

- Stay Hydrated: Using supplemental oxygen can sometimes dry out nasal passages. Discuss with your doctor whether a humidifier bottle (a small bottle of distilled water attached to the concentrator) is appropriate for your needs.

- Travel Smart: If using a portable concentrator for travel, ensure all batteries are fully charged, carry spare batteries, and confirm airline policies well in advance. Keep your prescription handy.

- Emergency Contact: Keep a list of emergency contacts, your healthcare provider's number, and the medical equipment supplier's number easily accessible.

By integrating these practices into your routine, you can maximize the benefits of your oxygen concentrator and ensure a safer, more reliable experience.

Your Next Breath: A Path Forward

The oxygen concentrator stands as a testament to human ingenuity, transforming the simple act of breathing for millions worldwide. From its intricate dance of pressure and adsorption to its quiet hum in a patient's living room, it performs a critical function: delivering the very essence of life.

Understanding how oxygen concentrators work isn't just about the technology; it's about appreciating the freedom and improved quality of life they offer. If you or someone you care for uses or might need supplemental oxygen, this knowledge empowers you to ask informed questions, ensure safe operation, and collaborate effectively with your healthcare team.

Always remember that an oxygen concentrator is a medical device. Its use, settings, and maintenance should always be guided by a healthcare professional. With the right knowledge and precautions, an oxygen concentrator can be a reliable and invaluable partner in navigating respiratory challenges, ensuring that every breath you take is a breath of fresh, concentrated possibility.